Stay Up to Date on the Latest Advances in Construction Technology

The construction industry is constantly changing and evolving, especially when it comes to technology trends. Now more than ever before, tech advances are helping contractors build their customer bases and finish projects more efficiently.

Newer technologies can also provide more transparency and visibility into what happens on a jobsite. This can help customers feel like they’re making informed decisions and give them more confidence in their contractor.

From on-site construction technology to 3-D printing, here are five types of technology that should be on every contractor’s radar.

1. Augmented Reality (AR)

1. Augmented Reality (AR)

Augmented reality (AR) is the blending of interactive digital elements with real-world objects by using something like a smartphone camera (think Snapchat filters or Pokémon Go). AR is being used for a lot more than video games these days, though. In fact, it can be used to drastically improve the training process and safety procedures on jobsites, as well as analyze problems and become part of the construction process. For example, a member of your crew could be looking around your jobsite, and then get data layered on top of their view showing information on temperature, landscape and the worksite.

2. Virtual Reality (VR)

AR’s cousin, virtual reality (VR), is a complete immersion experience that puts a user into an entirely digital world. This would be like putting on a pair of goggles and feeling as though you are actually moving and walking in different environments, completely removed from the world around you. Imagine being able to train and test on the jobsite and then reboot and start over — that’s possible with VR tools. This could make training a lot more specific to the actual jobsite, helping your team learn without real-life risks.

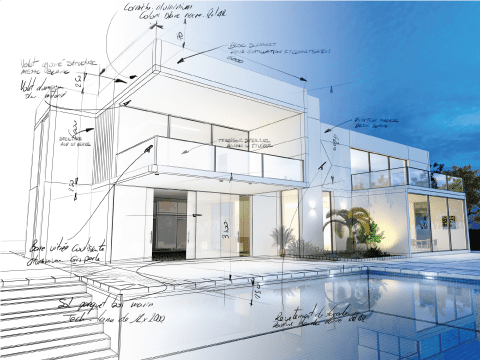

Contractors can even virtually walk through a jobsite before it physically exists. Because the tech allows contractors to create and problem solve projects in a virtual space before applying them on a physical jobsite, they see and resolve issues before ever purchasing materials or laying foundations.

3. 3-D Printing

3. 3-D Printing

3-D printing is a construction technology that allows you to create a three-dimensional solid object from a digital file. With greater accessibility to 3-D printers, businesses are able to construct prototypes of jobs before getting to the actual site. This can help with visualization, concepting and project management.

The technology might also lower supply costs and final customer prices, as well as reduce waste because it uses a manufacturing process where only the necessary materials are used. This printing may also help with more streamlined customer communication

because it allows you to provide a more realistic look at the final product.

4. Wearables and Connected Worksites

Another construction technology trend is finding solutions that connect those on the jobsite — whether that’s by streamlining projects, communication or processes. Connected worksites are quickly becoming the norm for contractors. This often starts with wearable construction technology. Here are a few different types according to Construction Dive:

- Sensing wearables: This technology often comes in the form of badges and sensors that can be attached to hardhats, glasses, shoes and other personal protective equipment. The goal of these wearables is to monitor physical, environmental, and biological conditions and provide data that informs you and your team members.

- Visual wearables: These glasses or other visual aids produce images for remote viewers and/or the person wearing the technology. This technology can be used to help with training and improves communication with offsite team members.

- Tactile wearables: These are suits that workers can wear to increase the user’s strength and durability, reducing the potential for strains and injuries. A progressive example might be a bionic suit that helps the wearer pick up heavy objects and easily operate heavy machinery.

5. Supplier Technology

Check with your supplier about the technology they have available to make it easier for you to order and receive materials. At ABC Supply, we offer ABC Connect, an online tool that integrates with leading industry software, to help with building estimates and placing orders. The program also includes Pictureit, a project visualization tool that allows homeowners to see what their finished projects will look like — hopefully making them feel more confident in their decisions.

You should also see if your supplier has technology to help with the delivery process. At ABC Supply, we provide delivery notifications and photo confirmations to give you peace of mind that your order arrives complete and correct. Learn more about our delivery process here.

Keep visiting the ABC Supply blog to learn more about how we can help you build your business.